Flexographic printing is widely considered a fast-growing form of printing, particularly within the packaging sector. Driven by its ability to print high-quality images on a variety of substrates at high speeds, this COVER STORY, adapted from MarketsandMarkets research, highlights the importance of this unique genre of printing to manufacturing.

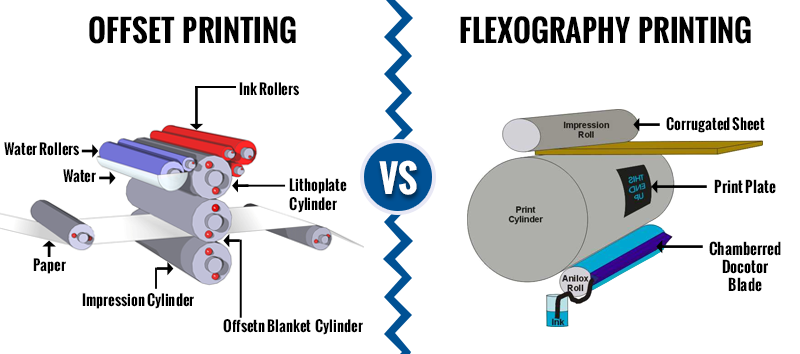

Flexographic printing, often called flexo, is a relief printing method that uses flexible printing plates to transfer ink onto various materials, primarily for packaging and labels. It’s a modern version of letterpress (offset printing) that uses fast-drying UV or water-based inks. Flexo printing is also known for its high-speed rotary printing process, which makes it suitable for printing on a wide variety of substrates such as paper, plastic, foil, BOPP film, MPET, PET, PVC, and tag material, amongst others, for packaging, labels, cartons, and other products.

It takes its name from its use of flexible materials such as plastics, rubbers, and UV-sensitive polymers for printing. As highlighted, this technology is widely used for package printing due to various benefits, such as high-quality printed images and high production speed. Hence, it can print on corrugated containers, folding cartons, labels and tags, paper sacks, and plastic bags.

(c) hirichlabels.vn

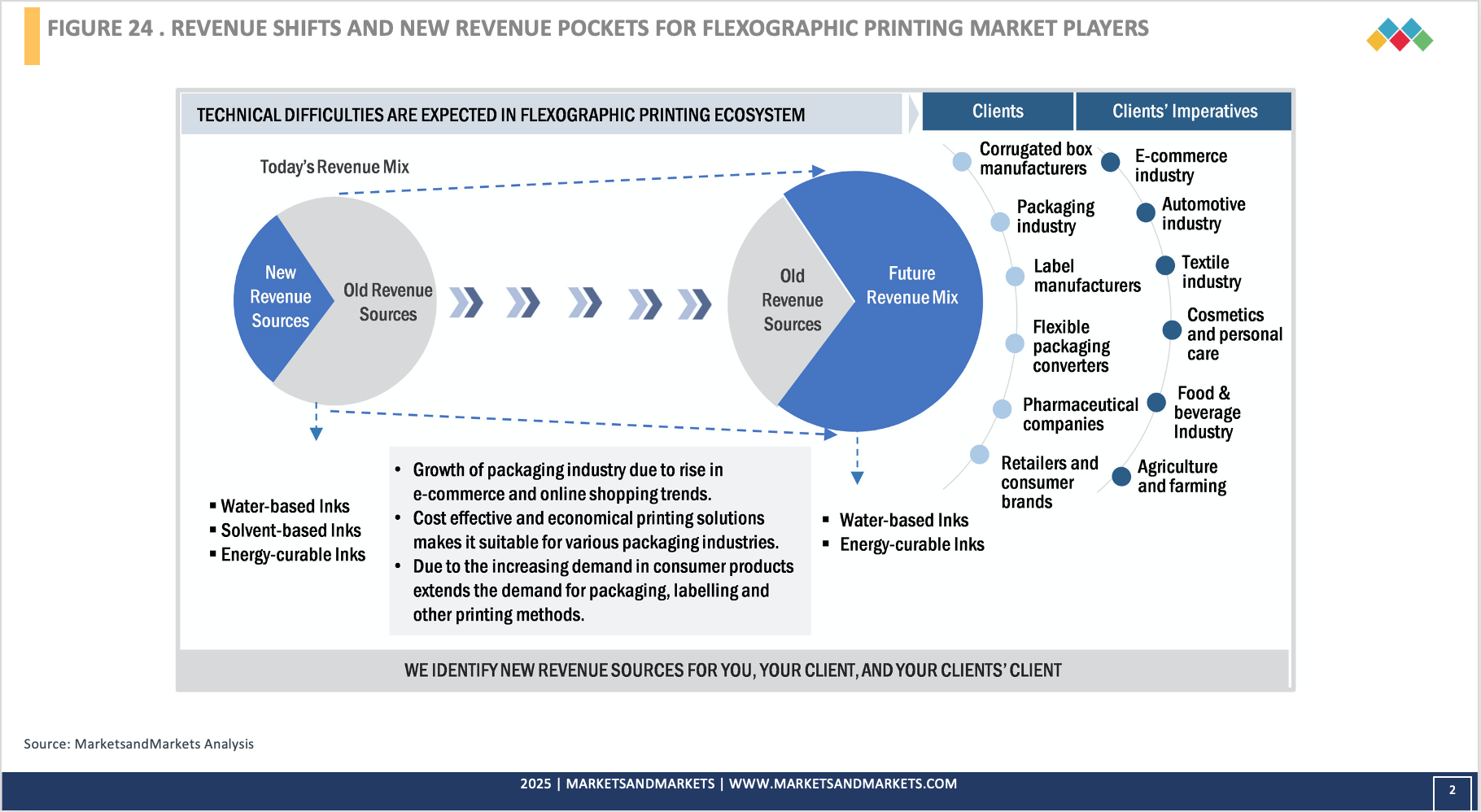

The packaging industry, driven by increasing consumer demand for packaged goods, has contributed significantly to the demand for flexographic printing. The packaging industry is continually evolving with the booming e-commerce industry and rising trends of online shopping. Not only that, technological advancements and flexo print suitability for high-volume, cost-effective production of flexible packaging, labels, and cartons contribute to its strong growth. This has led to an increase in demand for packaging materials to protect and deliver products. The choice of packaging materials can vary depending on the intended use, such as for transport, distribution, or consumer packaging. Industry has also seen a rise in demand for eco-friendly packaging solutions as companies become more aware of the need for sustainable environmental practices.

According to MarketsandMarkets, the Global Flexographic Printing Market in terms of revenue was estimated to be worth $8.7 billion in 2023 and is poised to reach $10.6 billion by 2028. The packaging industry is greatly influenced by the economic growth of sectors such as food processing, personal care, and pharmaceuticals, which create opportunities for market expansion and drive growth.

REVENUE SHIFTS AND NEW REVENUE POCKETS FOR FLEXOGRAPHIC PRINTING MARKET PLAYERS

Flexographic printing is known for its ability to provide efficient and economical solutions for various printing needs, where cost-efficient printing is one of the significant drivers for the flexographic printing market. It can achieve high production speeds, making it suitable for large volume runs. This speed allows for quick completion of print jobs, reducing labour and time costs per unit printed.

The setup costs for flexographic printing are relatively low compared to some other printing methods, especially for longer print runs. Once the press is set up and the plates are prepared, the process can be highly automated, minimizing manual intervention and associated labour costs.

Modern flexographic printing processes are becoming more efficient in terms of ink usage and reduced material waste. This contributes to cost savings by minimizing the amount of ink and substrate waste during the printing process. Advances in flexographic printing technology are leading to improved print quality, which is essential for maintaining a professional appearance while keeping costs down. The cost advantages of flexographic printing allow printing companies to offer competitive pricing to their clients, attracting more business and helping them maintain a strong market position.

Flexographic printing is a highly flexible and cost-effective method, well-suited to meet the demands of emerging markets. For example, Asia Pacific and African regions are experiencing rapid economic growth, resulting in increased consumer spending power and demand for various consumer products, including packaging, labels, and other printed materials. This has created many opportunities for flexographic printing to cater to these needs.

(c) Camelotprint.com

One of the major industrial growths supporting the printing and packaging industries is the growth of the consumer goods industry. As the demand for consumer goods such as packaged foods, beverages, cosmetics, and household products increases due to rising middle-class populations and increasing urbanization, the demand for printing labels, packaging materials, and other promotional materials also rises.

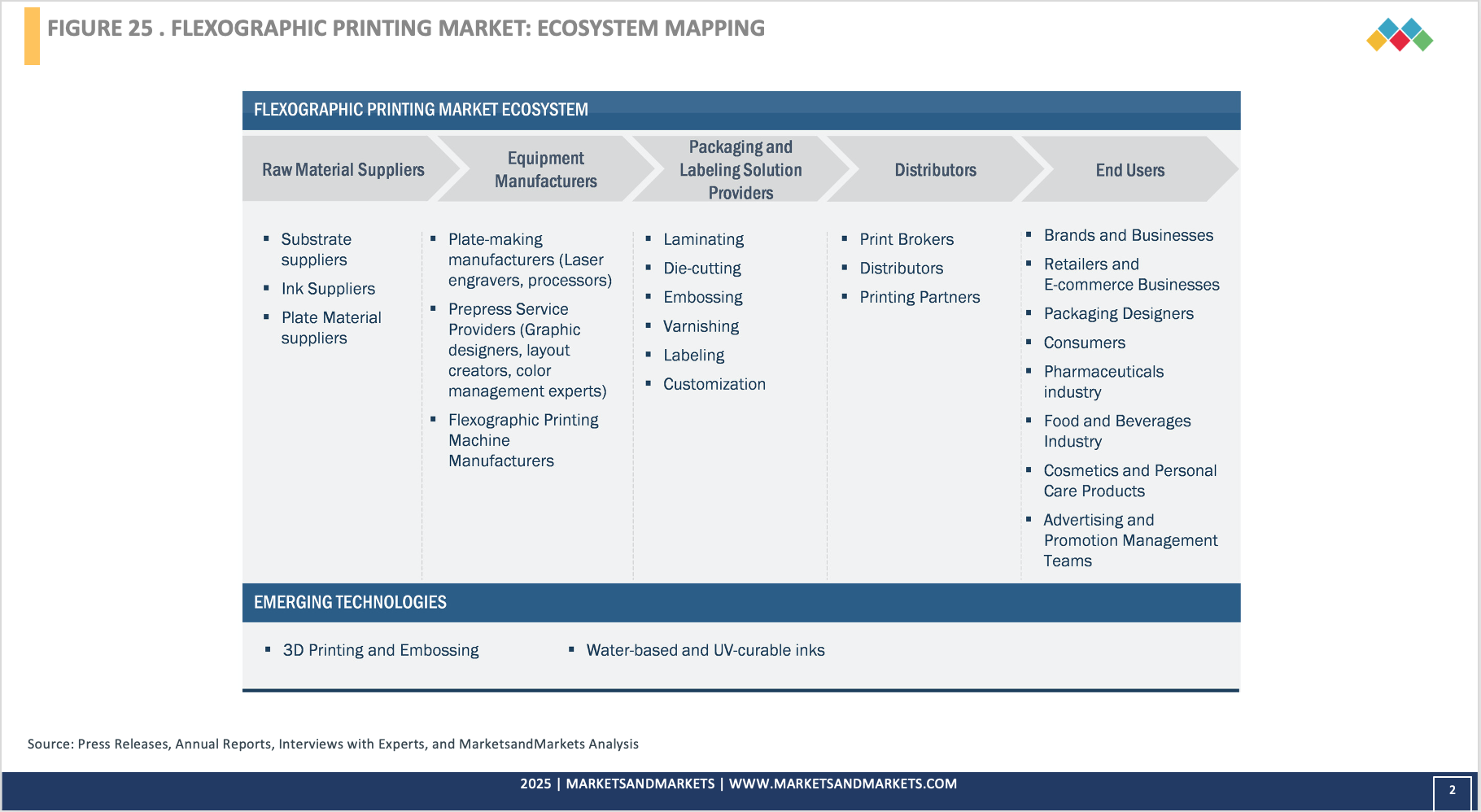

FLEXOGRAPHIC PRINTING MARKET: ECOSYSTEM MAPPING

Flexographic printing is widely used in the food and beverage industry for various packaging and labeling applications. Given the rapid expansion of regions such as the Asia Pacific food and beverages industry to meet the demands of the growing population, flexographic printing is commonly used in this sector, driving the demand for the flexographic printing market in the region.

Many emerging markets are establishing or expanding local manufacturing and production facilities. Flexographic printing allows these facilities to create packaging and promotional materials locally, reducing shipping costs and lead times. Moreover, as people in emerging markets move to urban areas, the demand for packaged and convenience goods rises, resulting in increased demand for the packaging of goods that can effectively serve the needs of urban consumers by providing visually appealing packaging and labels.

Businesses seeking to stand out on crowded shelves demand unique packaging and branding. Innovations in flexographic printing technology enable complex designs, textures, and patterns with improved print quality, finer details, and better colour accuracy. This enhances the visual appeal of printed materials, with three-dimensional printing helping to reproduce realistic illustrations. Compared to traditional printing processes, three-dimensional printing is faster, reduces waste by utilizing most of the materials, and helps achieve sustainability in printing processes. The image quality produced by three-dimensional printing processes is better than that of traditional methods. Innovative flexographic printing methods have contributed to more sustainable practices in the industry. The use of water-based inks, biodegradable materials, and energy-efficient processes aligns with the growing demand for environmentally friendly printing solutions.

3D PRINTING AND EMBOSSING

3D printing and embossing are innovative technologies integrated into the flexographic printing process to enhance printed materials’ visual and tactile aspects. These technologies add depth, texture, and unique effects to packaging, labels, and other printed products. 3D printing and embossing create visual depth and intricate textures that elevate the overall appearance of printed materials. This effect enhances the visual appeal of packaging and labels, making them more attention-grabbing on the shelf. Embossed textures generated through these technologies provide a tactile experience for consumers.

Flexographic printing can integrate 3D printing and embossing to create customized packaging solutions in which brands can tailor packaging designs to specific events, promotions, or individual customer preferences. 3D printing and embossing enable the creation of limited-edition packaging and labels that appeal to collectors and consumers looking for exclusive products. It is also used to create realistic prototypes and mockups of packaging designs.

WATER-BASED AND UV-CURABLE INKS

Water-based and UV-curable inks are considered more environmentally friendly alternatives to solvent-based inks. Water-based inks have lower volatile organic compounds (VOCs) levels, reducing air emissions and potential health risks. UV-curable inks contain little to no solvents and release fewer harmful environmental emissions. Using water-based and UV-curable inks helps flexographic printers decrease their carbon footprint and contributes to a cleaner and healthier printing process. UV-curable inks dry almost instantly when exposed to UV light, allowing for faster production speeds and reduced drying-related delays. Similarly, water-based inks also dry relatively quickly, contributing to improved efficiency. Water-based and UV-curable inks bond quickly to various substrates, ensuring good adhesion and durability on various materials.

The printing industry is constantly evolving, driven by the increasing demand for innovative printing. Among the various segments of the industry, flexographic printing is particularly influenced by this trend. As consumer preferences evolve rapidly, businesses strive to differentiate themselves in the competitive market. Technological advancements cater to this need by providing innovative printing methods.

About MarketsandMarkets™

MarketsandMarkets™ was founded in 2009 with a simple, yet powerful, idea – every disruption is inherently the source of game-changing business opportunities. At that time, everybody was talking about disruptive trends such as AI, IoT, 3D printing, nanotech, robotics, etc., but nobody was certain about the business opportunities associated with them. Upon sensing this significant white space, MarketsandMarkets started exploring these emerging and fast-growing opportunities and soon realized that it was part of a much bigger game. It figured out that the B2B economy was just beginning to undergo a dramatic transformation, wherein roughly $25 trillion of new revenue sources would emerge by the end of 2030. So, the firm embarked on a journey to help B2B companies monetize their play in this phenomenon.

During the past 16 years, MarketsandMarkets™ has worked with more than 10,000 companies and created $140+ billion of revenue impact for them. Consequently, it has evolved from being a market research publisher to a growth-enabling firm. Hence, it moulded its entire corporate culture around “GIVE growth” to promote a growth mindset among its 1500+ people workforce. Earlier this year, it made a formal transformation into one of America’s best management consulting firms as per a survey conducted by Forbes, evidently as the only India origin startup in the list of 200 firms. Even among these 200 peers, MarketsandMarkets™ stands apart as a blue-ocean alternative because of its unique intellectual property called Knowledge Store – A primary research-driven AI-enabled market intelligence platform meant for growth-minded executives.